we are professional mold manufacturer

Our Professionals:

1. Making interchangeable cores mold : a most effective and cost-saving manufacturing process. Suitable for customers looking for “more variety but less quantity” solution. With only one mold, it can efficiently generate different kinds of products,

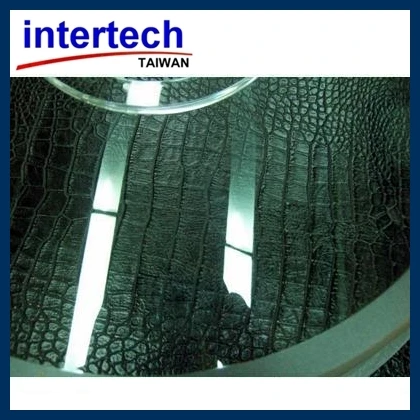

2. Making high transparent PC, Acrylic, PMMA, PET.. parts mold with high gloss polishing and Mold-Tech texture on parts surface, applied mostly in lighting parts, outdoor LED parts projects.

3. Making gas assisted injection molds and products projects …mostly applied in projects like the thick handles, monitors, the frame of TV cabinet etc, which prevents the shrinkage mark, improves the strength of the parts and saves material costs.

4 Medical silicone and rubber molds/products making : We manage both “solid” and “liquid” silicone rubber material meeting the standard of RoHS, FDA and REACH, and can be applied like skincare parts, medical earplugs, nipple pacifier, check valve, diving mask.