Need 3D drawings provided by customer to start our mold engineering works.

Need 3D drawings provided by customer to start our mold engineering works. If customer do not have 3D drawings but with samples on hands, we can also start our works with the samples by our reverse engineering technology.

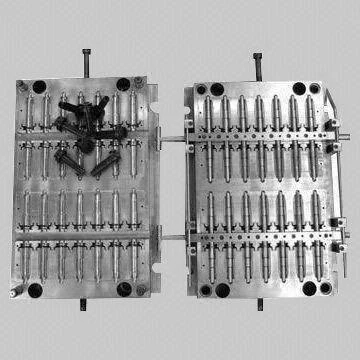

Using German,Sweden or Japan imported steel, including Buderus, Assab, AISI & JIS (including preharden steel and fully harden steel), P20 (=1.2311), H13 (=1.2344), Starvax 420 (=stainless steel) as mold base to create enough hardness mold.

Mold engraving is provided, including Date stamps(year and month), logotype, etc.

Capable in dealing with many different plastic raw materials (with RoHS, REACH-compliances, if need to use recycle plastic raw materials can be discussed) such as ABS, PC, PP, POM, PVC, PE, PP, HIPS, GPS, PC+ABS, NY6, NY6+GF, NY12, NY12+GF, NY66, NY66+GF, PBT, PET, PBT+GF, TPU, TPR, PMMA…etc.

FAQ

1. Besides molds, do you generate products as well?

Yes, we can make your projects here in our factory, Taiwan for you. But we only make it from making a new mold...then, from above new mold, making parts out of it. We make the production job for our customers in Taiwan. In other words, we do not have any existing mold. In short, we produced customized molds and products but we also provide our customers reverse engineering service.

2. How can I get the quote?

First, we need our customers provide their technical data like 2D, 3D drawings or samples. After receiving your project, our experienced and professional team will start to study and evaluate it. During this time, our team will keep discussing with the designers to make sure that every details are clear. Finally, we will give our customers quotation reports.

3. Does your company provide design service?

Absolutely yes. We have helped countless customers from Europe and North American to invent their new products. Our experienced engineers give our customers useful suggestion to help them solve the problems that they encounter when designing and process the molds and products.

4. Why is your price so competitive?

First of all, what we are famous for is that we produce interchangeable core mold, which needs not only precision work but also flexible team work to adjust to what our clients really want. Also, all of our steel is from Japan and Germany and all processing steps are carried in Taiwan under the supervision of our professional engineers. We appreciate that all of our customers emphasized on quality and efficiency and that's why our company wants provide too.

To know us more please contact us with your ideas / projects / drawings, so that we can start our studying / engineering job...

To know us more, please visit

www.taiwanmoldmaker.com; www.intertech.net.tw